Dislocations interaction induced structural instability in intermetallic Al2Cu (金属间化合物Al2Cu中位错相互作用诱导结构不稳定性行为)

Dislocations interaction induced structural instability in intermetallic Al2Cu (金属间化合物Al2Cu中位错相互作用诱导结构不稳定性行为)

Qing Zhou, Jian Wang, Amit Misra, Ping Huang, Fei Wang & Kewei Xu

npj Computational Materials 3:24 (2017)

doi:10.1038/s41524-017-0030-2

Published online:04 July 2017

Abstract| Full Text | PDF OPEN

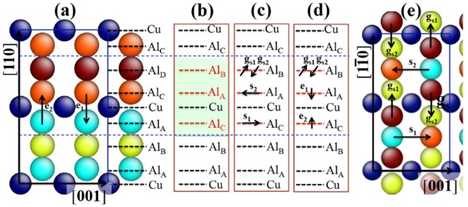

摘要:金属间析出物广泛应用于调控结构合金的力学性能,但其在塑性变形过程中常常不稳定。本研究通过原子尺度模拟,阐明了模型体系Al2Cu中与位错运动相关的金属间析出物结构不稳定机制。非共面<001>位错偶极子在塑性变形过程中的相互作用引起了异常反应:产生了空位,同时出现了与位错核心变化相关的<001>位错攀爬和集体滑移,并伴随着出现了大规模原子重排(atomic shuffle)——造成了金属间化合物Al2Cu的结构不稳定。随着非共面位错分离不断减少和温度持续升高,这种位错诱导结构不稳定性变得更为严重,并且该变化规律也可能存在于其它非立方金属间化合物的位错诱导结构不稳定过程。

Abstract:Intermetallic precipitates are widely used to tailor mechanical properties of structural alloys but are often destabilized during plastic deformation. Using atomistic simulations, we elucidate structural instability mechanisms of intermetallic precipitates associated with dislocation motion in a model system of Al2Cu. Interaction of non-coplanar <001> dislocation dipoles during plastic deformation results in anomalous reactions—the creation of vacancies accompanied with climb and collective glide of <001> dislocation associated with the dislocation core change and atomic shuffle—accounting for structural instability in intermetallic Al2Cu. This process is profound with decreasing separation of non-coplanar dislocations and increasing temperature and is likely to be operative in other non-cubic intermetallic compounds as well.

Editorial Summary

Intermetallics: dislocation climb promotes precipitate dissolution(金属间化合物:位错攀爬促进了析出物溶解)

金属间析出物的位错因相互作用而攀爬(并非滑移),留下了诸多缺陷。来自中国西安交通大学的Qing Zhou团队及其美国合作伙伴,采用分子动力学模拟,研究了铝-铜合金变形过程中金属间析出物位错的相互作用机制。他们的研究表明,非共面位错是靠攀爬(而非传统的滑移)进行相互作用的,之后再沿着新的原子平面滑移,位错并没有相互抵消,反而产生了空穴。温度升高,缺陷形成加快,位错核心得以扩展,空穴簇也变得更大,促进了析出物溶解。因此,深入研究变形过程中的金属间化合物稳定性,有可能帮助避免采用析出物强化合金时出现的失效问题。

Instead of gliding, dislocations in intermetallic precipitates interact to climb, leaving defects behind. Qing Zhou and colleagues at Xi’an Jiaotong University in China and their collaborators in the United States of America used molecular dynamics simulations to investigate the interactions of dislocations in intermetallic precipitates in aluminium-copper during deformation. They showed that instead of traditional glide, dislocations that do not lie on the same plane can interact by climbing then gliding along a new atomic plane without cancelling each other out, leaving vacancies behind. This defect creation happened faster at higher temperatures, creating extended dislocation cores and vacancy clusters that could facilitate precipitate dissolution. Research into intermetallic stability during deformation may thus help us avoid failure of alloys strengthened with precipitates.

沪公网安备 31010502006565号

沪公网安备 31010502006565号