Spatial correlation of elastic heterogeneity tunes the deformation behavior of metallic glasses (弹性非均匀性的空间相关性对金属玻璃变形行为的调节)

Spatial correlation of elastic heterogeneity tunes the deformation behavior of metallic glasses (弹性非均匀性的空间相关性对金属玻璃变形行为的调节)

Neng Wang, Jun Ding, Feng Yan, Mark Asta, Robert O. Ritchie &Lin Li

npj Computational Materials 4:19 (2018)

doi:10.1038/s41524-018-0077-8

Published online:06 April 2018

Abstract| Full Text | PDF OPEN

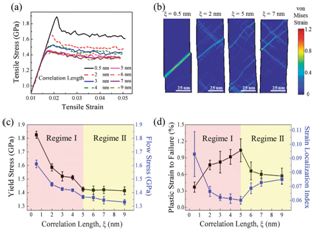

摘要:金属玻璃(MG)具有很高的强度,然而剪切带的出现极大降低了该类材料的拉伸塑性。本研究旨在提高MG内在异质性,以促进分布式流动,从而为改善单片MG的延展性提供新的可能。本文研究了非均质无定型构型引起的弹性各向异性对MG形变性能的影响,并利用多尺度模拟方法对体系延展性做了相关研究。通过原子尺度的计算模型发现,Cu64Zr36 MG在纳米尺度下呈现出了高度异质的高斯型剪切模量分布,而其中局部的柔性区域很大程度伴随着非弹性剪切形变的出现。对剪切变形区进行介观尺度的动力学模型计算发现,纳米尺度剪切形变转化为剪切带形变由局域剪切模量的空间异质性决定。为获得最佳拉伸塑性,作者定义了弹性异质性的临界空间相关长度。该临界长度与剪切带形成的转变节点相关,该临界值可从应力诱导的成核生长、结构决定的应变渗透与塑性流动的弹性软点饱和度等性能进行表征。这一发现对于深化理解空间异质性与MG形变过程的关系具有重要意义。本方法可通过调控材料本征的异质性来增强高强度金属合金的拉伸塑性,从而促进新型延性单片MG的设计和开发。

Abstract:Metallic glasses (MGs) possess remarkably high strength but often display only minimal tensile ductility due to the formation of catastrophic shear bands. Purposely enhancing the inherent heterogeneity to promote distributed flow offers new possibilities in improving the ductility of monolithic MGs.Here, we report the effect of the spatial heterogeneity of elasticity, resulting from the inherently inhomogeneous amorphous structures, on the deformation behavior of MGs, specifically focusing on the ductility using multiscale modeling methods.A highly heterogeneous, Gaussian-type shear modulus distribution at the nanoscale is revealed by atomistic simulations in Cu64Zr36 MGs, in which the soft population of the distribution exhibits a marked propensity to undergo the inelastic shear transformation. By employing a mesoscale shear transformation zone dynamics model, we find that the organization of such nanometer-scale shear transformation events into shear-band patterns is dependent on the spatial heterogeneity of the local shear moduli.A critical spatial correlation length of elastic heterogeneity is identified for the simulated MGs to achieve the best tensile ductility, which is associated with a transition of shear-band formation mechanisms, from stress-dictated nucleation and growth to structure-dictated strain percolation, as well as a saturation of elastically soft sites participating in the plastic flow. This discovery is important for the fundamental understanding of the role of spatial heterogeneity in influencing the deformation behavior of MGs. We believe that this can facilitate the design and development of new ductile monolithic MGs by a process of tuning the inherent heterogeneity to achieve enhanced ductility in these high-strength metallic alloys.

Editorial Summary

Metallic Glasses: The role of soft spots (金属玻璃:软点的作用)

该研究模拟揭示了弹性软点与金属玻璃形变过程之间的关系。无定形材料通常具有低的拉伸塑性和抗疲劳强度,即该类材料通常具有弱应变活化剪切带,且会导致材料迅速失效。目前,来自阿拉巴马大学、劳伦斯伯克利国家实验室和加利福尼亚大学的一个研究小组计算研究了金属玻璃(特别是Cu64Zr36)本征的空间异质性与剪切带形成之间的关系。随着材料异质性之间空间关联性的增强,以及弹性软点和硬点区域的扩大,作者们观察到在材料软点处,软点数量的降低削弱了材料延展性,且应力诱导的成核生长和剪切带增长开始向应变渗透转变。作者发现,协同调控软点数量和软点空间分布可以帮助改善金属玻璃的延展性。

Simulations shed light on the connection between elastically soft spots and the deformation of metallic glasses.Amorphous materials generally suffer from low ductility and fatigue strength: relatively low strain activates shear bands that quickly lead to failure. Now a team from the University of Alabama, Lawrence Berkeley National Laboratory and the University of California, investigate computationally the connection between the intrinsic heterogeneity of metallic glasses (and in particular Cu64Zr36) and the formation of shear bands. As the spatial correlation of the heterogeneity increases, and the regions of elastically soft and hard spots expand, the authors observe a transition from stress-driven nucleation and growth of the shear bands (resulting in increased ductility) to strain percolation, initiated in the soft spots (leading to reduced ductility as the number of soft spots has decreased). Combined with ways to control the number and distribution of soft spots, this insight could help improve the ductility of metallic glasses.

沪公网安备 31010502006565号

沪公网安备 31010502006565号