Continuum understanding of twin formation near grain boundaries of FCC metals with low stacking fault energy (在连续介质尺度上揭示低堆垛层错能量的FCC金属晶界处孪晶形成机制)

Continuum understanding of twin formation near grain boundaries of FCC metals with low stacking fault energy (在连续介质尺度上揭示低堆垛层错能量的FCC金属晶界处孪晶形成机制)

Jaimyun Jung, Jae Ik Yoon, Jung Gi Kim, Marat I. Latypov, Jin You Kim & Hyoung Seop Kim

npj Computational Materials 3, Article number: 21 (2017)

doi:10.1038/s41524-017-0023-1

Published online:24 May 2017

Abstract| Full Text | PDF OPEN

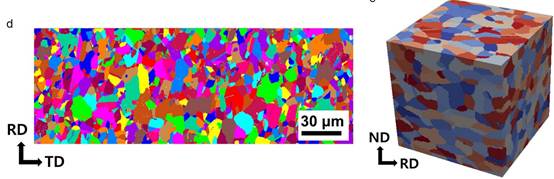

摘要:低堆垛层错能量的面心立方金属晶界处,常可观察到变形孪晶发生(deformation twinning)。孪晶发生于晶界处的一个可能的促进因素是变形时的晶粒间相互作用。但这种相互作用对孪晶演化有何影响,人们却不太清楚。同时,微结构特征与孪晶形成之间的因果关系尽管已做了大量实验和模拟研究,却仍缺乏对大量晶粒聚集体之间清晰关系的理解。本研究通过室温下单轴拉伸变形的孪晶诱导可塑钢全场晶体可塑性模拟,探查了晶界附近的形变孪晶,从而表征了晶粒间相互作用的微观力学行为。首先通过电子反散射衍射技术观察了微结构,获得数据后,再经微结构合成建造技术(synthetic microstructure building),重建了统计学上等效的微结构。通过分析晶粒间微观力学响应,来研究拉伸变形条件下微结构大量要素在总体上的孪晶发生行为。模拟结果分析表明,晶粒相互作用可通过晶边处的应力转移或晶界附近的应力局域化,来改变晶界附近的局部力学行为。

Abstract: Deformation twinning from grain boundaries is often observed in face-centered cubic metals with low stacking fault energy. One of the possible factors that contribute to twinning origination from grain boundaries is the intergranular interactions during deformation. Nonetheless, the influence of mechanical interaction among grains on twin evolution has not been fully understood. In spite of extensive experimental and modeling efforts on correlating microstructural features with their twinning behavior, a clear relation among the large aggregate of grains is still lacking. In this work, we characterize the micromechanics of grain-to-grain interactions that contribute to twin evolution by investigating the mechanical twins near grain boundaries using a full-field crystal plasticity simulation of a twinning-induced plasticity steel deformed in uniaxial tension at room temperature. Microstructures are first observed through electron backscatter diffraction technique to obtain data to reconstruct a statistically equivalent microstructure through synthetic microstructure building. Grain-to-grain micromechanical response is analyzed to assess the collective twinning behavior of the microstructural volume element under tensile deformation. Examination of the simulated results reveal that grain interactions are capable of changing the local mechanical behavior near grain boundaries by transferring strain across grain boundary or localizing strain near grain boundary.

Editorial Summary(自然研究宣传稿)

Metals: grain neighbours influence twin formation during deformation(金属:相邻晶粒的相互作用影响变形过程中的孪晶形成)

不利于孪晶形成的晶粒却由于周围的晶粒相互作用显示出对孪晶形成的促进作用。来自韩国浦项科技大学的金贤勋及其同事,基于变形钢的位错滑移和孪生机制,对由各种取向晶粒合成而来的金属微观结构中变形行为进行模拟。孪晶首先起始于晶粒边界附近并依赖初始晶粒的取向,但随着进一步的变形,晶界一侧强大的孪晶活性,又在该晶界的另一侧引发了强烈的孪晶活性。甚至当边界另一边的晶粒不利于孪晶发生的时候,孪晶也照样能够发生。因此,研究相邻晶粒间的邻接关系很可能有助于优化由孪晶形成的合金。

Grains that should not favour twin formation exhibit twinning as a result of surrounding grains acting on their boundaries. A team led by HyoungSeop Kim at the Pohang University of Science and Technology in the Republic of Korea simulated the deformation of synthetic metallic microstructures with many grains of different orientations, based on steels that deform by both dislocation slip and twinning mechanisms. Twinning first started near grain boundaries and depended on initial grain orientation but, with further deformation, strong twin activity on one side of a boundary triggered strong twin activity on the other side of that boundary. This happened even when the grain on the other side of the boundary was unfavourable to twinning. Taking into account grain neighbourhood may therefore help in optimising twin-forming alloys.

沪公网安备 31010502006565号

沪公网安备 31010502006565号